It is so easy to find something to sew for my granddaughters. That really came home to me when I gifted Carley with her mini NCW . I always give the boys something special as well so they certainly aren't ignored. But, this time Zack asked me, " Bunbun, could you make me something?" and of course I said , "yes, I will make something for both you and your big brother." Enter the Retreat Bag:

Some call this a Dopp Kit. My brothers used to call theirs d-----bags. I call them cute and a perfect gift you can make for a young man.

The Retreat bag is a FREE PDF pattern from Emmaline bags. Yes, free! I am not sure there is anyone else out there who has anything similar. At least I haven't seen it! It comes in two sizes and I will be making the smaller size bag for the boys. There is a frame that goes into the top of the bag so that when the zipper is closed you have that classic fold on the corners. I have seen some choose to go without the frame.Those look good but I think the frame adds a bit of snap and professionalism to the finished item. (NAYY here) I have also seen some add straps and make this into a women's handbag as well, very cute!

For my exterior fabric I have chosen a cordovan red faux leather that I have sewn before. It's masculine bit of color should work well.

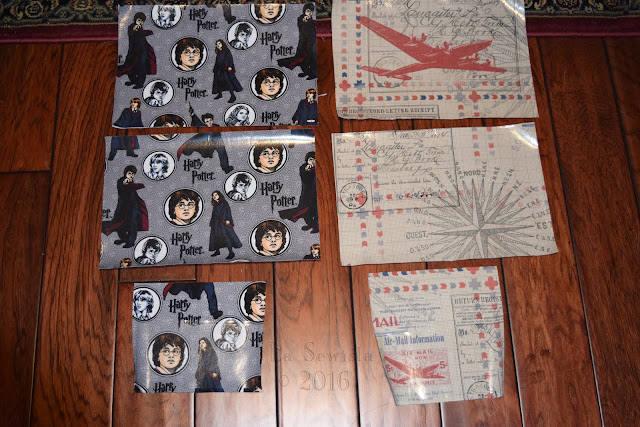

The lining is where some imagination gets played out. One of my grandsons is crazy for airplanes to the point where he has his first job at the local airport. He cleans the offices and gets flight lessons in exchange! Graham's lining will be this "aviation" print .

My other grandson is an avid reader. He is in third grade and had read every Harry Potter novel by the end of second grade. We should all be thanking J. K. Rowling for planting the love of reading in the hearts of so many children. Zack's will be a Harry Potter print. Both came from Joanns. They each have red tones in them that should work well with the leather color. If you are going to fussy cut printed fabric to highlight the motifs, make sure you get extra. I got twice the amount need but have enough left to make an NCW lining. Fussy cutting adds so much to a made at home bag. Also, be careful with directional prints and cut them one layer at a time so each side will face up.

I decided to "vinylize" (my word) the lining fabrics in order to make the inside wipeable/cleanable. The first step was buying a by the yard product made by Pellon called Vinyl Fuse. I found a clearance bolt at JAs and with the overall discount paid 1.50 a yard, yahoo! I bought a lot! If you can't find that I believe the same product is now marketed in pieces and sold in a box. I was a bit intimidated by the product but once I tried it I found it really wasn't tricky at all. I was expecting to maneuver a big sticky mess . Think Contac Paper. Instead I found the vinyl quite cooperative. I followed the directions exactly. It's important to use the paper the vinyl comes with as a "press cloth" between it and the iron. Don't throw it out. It will come in handy for pressing seams later.

I didn't know how the vinyl would react to the heat so laid down a layer of drill cloth on the steam press for this project. Hey, it's new after all! FWIW, I did the first vinyl fusing with my regular iron and it worked just fine. But the steam press really shined with this task. Above is the steam press fusing the interfacing on the bag piece.

It's really important to fuse all the interfacing to the pieces before fusing the vinyl. Just trust me on this one. Above you can see the vinylizing set up. Drill cloth, exterior fabric FACE UP, and lastly the release paper/vinyl combo with the vinyl facing down. 8 seconds down with the press, no steam and voila! The red arrow points to the vinyl that didn't get attached and the green is the release paper. You can see I had excess vinyl on the edges and it easily pulled off of the drill cloth while the pieces were still warm. This process truly made no mess and was quite easy. It would just take a bit more time with an iron but just as neat and clean. One thing to be really careful of before putting down the vinyl is that there are no pieces of lint or thread on the fabric. They will be there for time eternal if not brushed off. Also, you will see the vinyl may look to be "loose" on areas of the release paper that rounded the edges of the bolt. Don't fret. It all presses out to perfect flatness. And really important,,,, no steam used here. I pressed the right side 8 seconds, flipped it over and pressed the wrong side 4 seconds, exactly as Pellon describes in the directions. I will definitely do this again. It was easy. The boy's bags will be wipeable inside and how good is that? They travel a lot with their families and these will really come in handy.

All is fused now with vinyl and interfacing. I blocked fused the large pieces so the vinyl is in the seam allowances. The pockets had the vinyl cut back from the seam allowances and from one half of the square that will be the lining of the pocket when sewn.

Here's a closeup of the fused pieces. I love how it prevents the edges from ravelling.

The exterior pieces had the vinyl, the fabric, fusible fleece and SF101 interfacing. How to keep the bulk down? I took a piece of batiste and cut it the same size and shape as the bag exteriors. I then fused the fusible fleece, with no seam allowances to the batiste. I turned it over and then fused the SF101, again with no seam allowances, to the other side. Now I will just stitch the batiste into the seam allowance of the bag, so basically a sewn in interfacing.

One thing I have I've been impressed with is the well thought out and "proven before market hit" way Indie bag designers use and specify interfacings. Most bags have at least two types, Many have three. But in nearly every pattern out there Pellon SF101 is used, A LOT. It is a woven interfacing and works well in these bags. I will honestly tell you that I don't use Pellon products in my garments but for these bags, the SF101 and the foams work really well. Also, I wanted to fuse my fleece to a separate fabric because on past projects I found it could pick up wrinkles while turning and handling during the construction process.

with permission of Emmaline Bags

Some call this a Dopp Kit. My brothers used to call theirs d-----bags. I call them cute and a perfect gift you can make for a young man.

The Retreat bag is a FREE PDF pattern from Emmaline bags. Yes, free! I am not sure there is anyone else out there who has anything similar. At least I haven't seen it! It comes in two sizes and I will be making the smaller size bag for the boys. There is a frame that goes into the top of the bag so that when the zipper is closed you have that classic fold on the corners. I have seen some choose to go without the frame.Those look good but I think the frame adds a bit of snap and professionalism to the finished item. (NAYY here) I have also seen some add straps and make this into a women's handbag as well, very cute!

For my exterior fabric I have chosen a cordovan red faux leather that I have sewn before. It's masculine bit of color should work well.

The lining is where some imagination gets played out. One of my grandsons is crazy for airplanes to the point where he has his first job at the local airport. He cleans the offices and gets flight lessons in exchange! Graham's lining will be this "aviation" print .

My other grandson is an avid reader. He is in third grade and had read every Harry Potter novel by the end of second grade. We should all be thanking J. K. Rowling for planting the love of reading in the hearts of so many children. Zack's will be a Harry Potter print. Both came from Joanns. They each have red tones in them that should work well with the leather color. If you are going to fussy cut printed fabric to highlight the motifs, make sure you get extra. I got twice the amount need but have enough left to make an NCW lining. Fussy cutting adds so much to a made at home bag. Also, be careful with directional prints and cut them one layer at a time so each side will face up.

I decided to "vinylize" (my word) the lining fabrics in order to make the inside wipeable/cleanable. The first step was buying a by the yard product made by Pellon called Vinyl Fuse. I found a clearance bolt at JAs and with the overall discount paid 1.50 a yard, yahoo! I bought a lot! If you can't find that I believe the same product is now marketed in pieces and sold in a box. I was a bit intimidated by the product but once I tried it I found it really wasn't tricky at all. I was expecting to maneuver a big sticky mess . Think Contac Paper. Instead I found the vinyl quite cooperative. I followed the directions exactly. It's important to use the paper the vinyl comes with as a "press cloth" between it and the iron. Don't throw it out. It will come in handy for pressing seams later.

I didn't know how the vinyl would react to the heat so laid down a layer of drill cloth on the steam press for this project. Hey, it's new after all! FWIW, I did the first vinyl fusing with my regular iron and it worked just fine. But the steam press really shined with this task. Above is the steam press fusing the interfacing on the bag piece.

It's really important to fuse all the interfacing to the pieces before fusing the vinyl. Just trust me on this one. Above you can see the vinylizing set up. Drill cloth, exterior fabric FACE UP, and lastly the release paper/vinyl combo with the vinyl facing down. 8 seconds down with the press, no steam and voila! The red arrow points to the vinyl that didn't get attached and the green is the release paper. You can see I had excess vinyl on the edges and it easily pulled off of the drill cloth while the pieces were still warm. This process truly made no mess and was quite easy. It would just take a bit more time with an iron but just as neat and clean. One thing to be really careful of before putting down the vinyl is that there are no pieces of lint or thread on the fabric. They will be there for time eternal if not brushed off. Also, you will see the vinyl may look to be "loose" on areas of the release paper that rounded the edges of the bolt. Don't fret. It all presses out to perfect flatness. And really important,,,, no steam used here. I pressed the right side 8 seconds, flipped it over and pressed the wrong side 4 seconds, exactly as Pellon describes in the directions. I will definitely do this again. It was easy. The boy's bags will be wipeable inside and how good is that? They travel a lot with their families and these will really come in handy.

All is fused now with vinyl and interfacing. I blocked fused the large pieces so the vinyl is in the seam allowances. The pockets had the vinyl cut back from the seam allowances and from one half of the square that will be the lining of the pocket when sewn.

Here's a closeup of the fused pieces. I love how it prevents the edges from ravelling.

The exterior pieces had the vinyl, the fabric, fusible fleece and SF101 interfacing. How to keep the bulk down? I took a piece of batiste and cut it the same size and shape as the bag exteriors. I then fused the fusible fleece, with no seam allowances to the batiste. I turned it over and then fused the SF101, again with no seam allowances, to the other side. Now I will just stitch the batiste into the seam allowance of the bag, so basically a sewn in interfacing.

One thing I have I've been impressed with is the well thought out and "proven before market hit" way Indie bag designers use and specify interfacings. Most bags have at least two types, Many have three. But in nearly every pattern out there Pellon SF101 is used, A LOT. It is a woven interfacing and works well in these bags. I will honestly tell you that I don't use Pellon products in my garments but for these bags, the SF101 and the foams work really well. Also, I wanted to fuse my fleece to a separate fabric because on past projects I found it could pick up wrinkles while turning and handling during the construction process.

All pieces are now vinylized, fused and ready to stitch. I will need to do some stitching samples before sewing all this vinyl and that is next!..........Bunny

This looks so fun! I've not had any luck with bag sewing but I'm always collecting bits of tips and tricks.

ReplyDeleteAnd that steam press! It's on my to-buy list!

I always wanted one, Nakisha, and now wonder how I did without it. It's a great tool for any sewist.

DeleteThank you for sharing all the tips on vinyl application. I'm going to give it a try :)

ReplyDeleteIt's really simpler than it looks. The only thing to make sure of is to have the correct side get the vinyl. It's easy to confuse them as my mind was automatically thinking interfacing which goes on the bottom of the fabric. Luckily I caught my error in time.

DeleteThis comment has been removed by the author.

ReplyDeleteLets try this again! The boys are going to love these bags! What a great idea. Thanks for the interfacing tips. Is the Pellon available at JoAnn's?

ReplyDeleteYes. I've seen it on the bolt called "Vinyl Fuse" and in with the interfacings. I've also seen it packaged in boxes on a nearby end cap.

ReplyDeleteI love this idea! My boys are 10 and 8 and this would be great as they get older and don't want their stuff mixed in with their little sisters' stuff when we go away. Did that airplane fabric come out of the quilting cottons at JoAnns? I actually grew up in Lancaster (it's where the kids Grammy and Grandad still live) - I would love it for lining!

ReplyDeleteIt was in with the "premium" quilting cottons at our Joanns.

DeleteThat vinyl fuse looks like a great product. I'm with you, I don't care for Pellon at all as it almost always bubbles when washed. But it should be great in this application.

ReplyDeleteWow Bunny this is an awesome help for these "dopp bags ". My son and hubby always use theirs. They will make great gifts for makeup bags too, because they open nicely and the fabric can be protected with vinyl.

ReplyDeleteI still have to experiment with needles and stitch length and will have that up as soon as I know what works. I have an idea for one for my husband. He has had the same bag for our entire marriage. It's still holding up but hey, it's time to move on!

DeleteWhat lucky boys! They will receive beautiful well-made thoughtful bags by their beloved bunbun.

ReplyDeleteDear Bunny, I love reading about your deep dive into bag making. I've taken a few Craftsy courses on bag making, but I always pick up additional tips from your posts. Love, love love!

ReplyDeleteLast night I quickly hit "publish" after reviewing two comments but only one comment published! I am so sorry to whoever was kind enough to share their thoughts here and didn't get their comment posted. I don't know if it was my error or Blogger. I hope you try again, whoever you are. All your comments are appreciated.

ReplyDeleteBoys need these kind of items but usually there are available in boring "men" colours (eg navy blue or black), so your creativity is exceptional and very well done. I bought some of the waterproofing stuff myself as I wanted to make a nice shower cap - as again all the designs in the shops are rather silly pink and polka dots and I wanted something personal and classy.

ReplyDeleteThanks, Bunny, for sharing all your interfacing tips. Your enthusiasm is contagious and now I have the bag bug, too. I don't believe I will ever get the crisp, professional results you've achieved but I will have fun trying! ;)

ReplyDeleteWith so many interfacing specs for these patterns, it's especially valuable to have your insights and experience. I've only used garment interfacing and didn't feel comfortable buying Pellon until you gave it the green light.

The love for your boys really shines in these bags! I'm so glad you're blogging again.